Frequently Bought Together

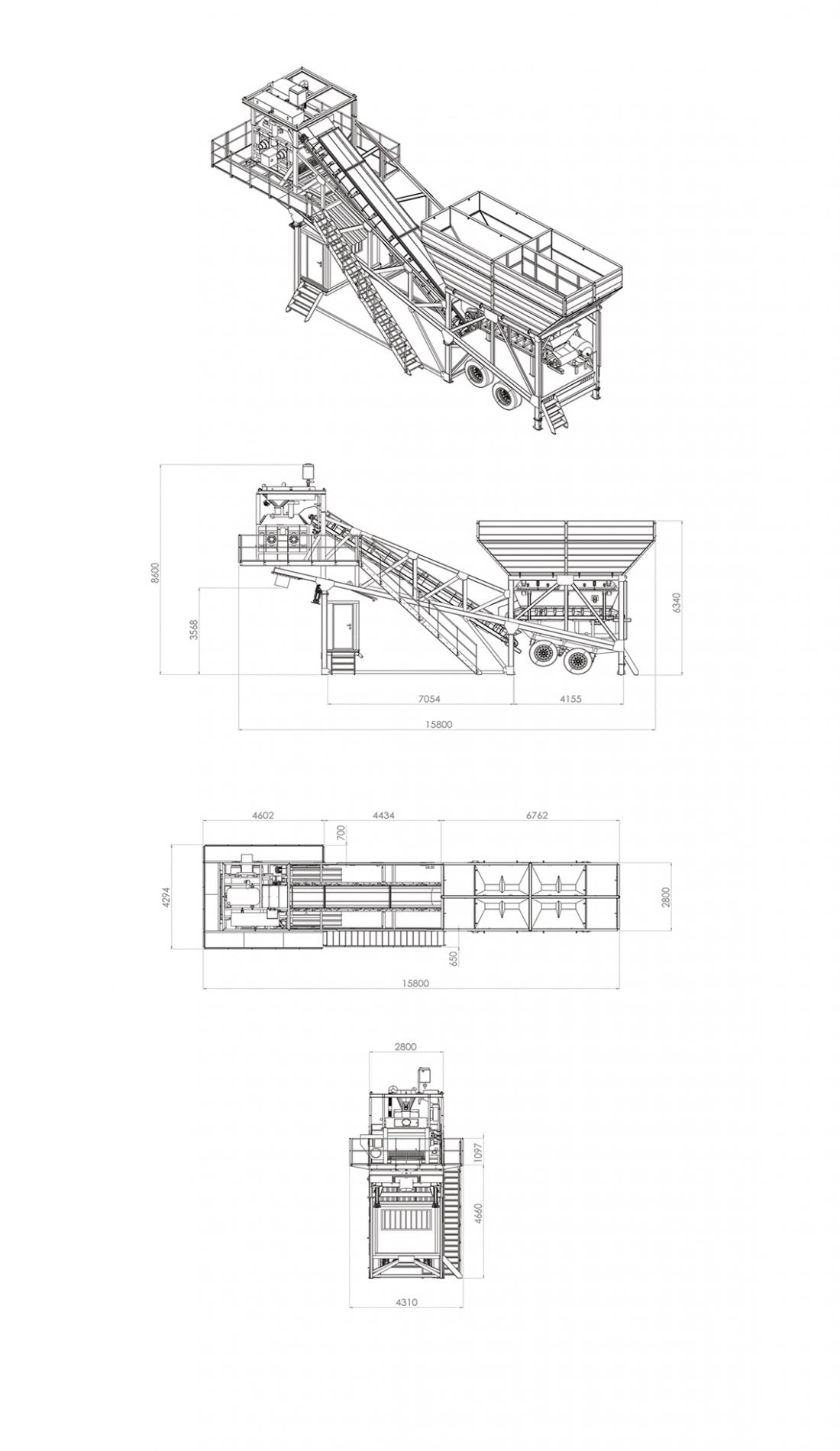

FASTMIX Mobile

A reliable and cost-effective plant, FASTMIX Mobile concrete batching plants are

distinguished by their easy transportability, quick installation and low-costs operating.

They are convenient for customers looking for a fast solution compared to stationary concrete plants, and also suitable for ready-mix concrete suppliers and various

construction sites. These concrete plants are the best suitable for construction projects

in which the production of concrete required is quite substantial. Like all other

concrete plants in FASTMIX range, the strength and reliability of the product are

guaranteed. In addition to the exceptional control of the construction process,

these concrete plants allow easy maintenance to guarantee a long life service.

They are each equipped with a twin shaft, planetary or turbo mixer, suitable for

the desired flow rate, providing fast mixing, homogeneous and high-quality

concrete production.

Our FASTMIX Mobile concrete plants produce compacted

concrete with a capacity ranging from 35 m3 to 100 m3 per hour. The storage and

weighing systems consist of four crossover hoppers. Granulates are transferred by using a chevron belt conveyor. Cement storage is provided by waterproof silos

equipped with dust filters, safety valve, level indicators, and aerator nozzles, etc..

The capacity and number of silos vary according to each plant, and the cement transfer

is provided by screw conveyors. All the equipment required to operate

our

FASTMIX Mobile concrete plants are pre-installed and pre-cabled including the air

compressor, cement, water and admixture pumps.

FASTMIX Mobile Advantages:

- Fast installation.

- High mobility.

- Compliance in international standards.

- Reduction in transportation and operating costs

- Resistance to the most extreme climatic conditions

- FASTMIX Module saves production time, installation-maintenance costs and

energy consumption.

| Model | Fastmix 100MB | |

|---|---|---|

| Maximum production capacity | m3/h | 100 |

| Volume of fresh concrete | m3 | 2 |

| Filling capacity | L | 3000 |

| Vibrated concrete capacity | L | 2000 |

| Vibrated concrete capacity | m3 | 50 |

| Volume per hopper | m3 | 4×12,5 m³ |

| Weighing hopper dimensions | mm | 3500x1750x2400 |

| Power transfer belt | Kw | 15 |

| Power strip dimensions | mm | 1000×11000 |

| Cement scale capacity | Kg | 1000 |

| Capacity toggle to adjuvant | L | 50 |

| Water scale capacity | L | 500 |

| Type of mixer | – | Double arbre |

| Air-conditioned control cabin | mm | 2400x2400x1750 |

| Air compressor | L | 500 |

| Adjuvant pump | Kw | 0.75 |

| Mixer motor power | Kw | 2×37 |

| Screw conveyor diameter | ø | 273 |

| Total weight | Ton | 28 |

| Transport | Camion remorque | |

| Electrical equipment | Schneider / Siemens | |

| Automatisme | AMM |